The stage is the world: ABUS chain hoists, EOT cranes, and suspended rail systems at the stage services in Berlin

In the leading roles of Wagner’s lavishly enacted opera “Tristan and Iseult”: singers and musicians of international distinction. In major supporting roles: Products of the company ABUS Kransysteme acting behind the curtains.

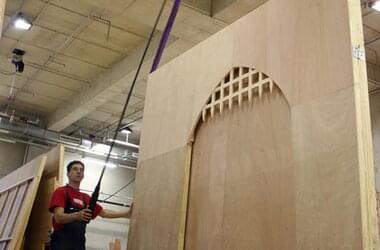

In 2010, 32 fixed chain hoists, two suspended rail systems, and four underslung EOT cranes started to move sceneries and props in the halls that the stage services of the Berlin Opera Foundation had recently moved into. In the newly refurbished workshops you will find a team of 200 experts in the varied fields of joinery, painting, millinery, and many more. They would normally work on six or seven stage sets at any given time and would built about sixty sets a year for different enactments.

The ABUS cranes play a supporting role in the mounting and handling of the stage parts some of which are of gigantic proportions: a row of fixed chain hoists of the ABUCompact series with a lifting capacity of 500 kg assists with replicating the stage setting and with lifting and lowering the backdrop exactly as it is going to be carried out during the play itself. Two suspended rail systems are available for further mounting works: the crane track is 24 metres long, the span is ten metres wide, and the lifting capacity is 500 kg. A crane of the ZHB-X type is used in the installation hall, the stooled-up crane bridge makes for optimum use of the available ceiling height. Two EHB type cranes are working in the joinery, they have vacuum lifters for operational elements. The crane track is more than 60 metres long enabling this EHB system to serve several machinery workstations.

The range of ABUS products employed is rounded off by four underslung EOT cranes of the DLVM type in the metalworking shop where the base frames for the stage sets are being built. In contrast to other ABUS EOT cranes these DLVM cranes are mounted directly on the ceiling instead of on columns. Thus the DLVMs are top end solutions even under difficult circumstances as to space and construction. These cranes have a span of nine metres, have two hoists of 500 kg lifting capacity each, and are radio controlled.

The amalgamation of several workshop sites into one central location by the Berlin Opera Foundation has created one of the biggest theatre workshops in Europe with a surface area of about 12,000 square metres. The whole production process benefited from synergy effects normally only associated with industrial production. Thus modern production and material handling technologies using ABUS crane systems and traditional craftmanship are happily married.