Mounting for pillar slewing jib cranes

Which crane mounting is suitable for my application?

We will show you the various options for floor mounting here:

| What will it be mounted to? | What crane types are possible? | Which load capacities and jib lengths are possible? | Which requirements does the customer have to meet? | Mounting |

| New building or floor of building, not yet constructed |

All | All load capacities and jib lengths | Laying the foundations | With anchor rods and template |

| New building or floor of building not yet constructed ideal for later crane installation |

All | All load capacities and jib lengths | Laying the foundations | With ideal anchor screws and template |

| Existing floor of building or concrete ceiling, reinforced normal concrete, no steel fibre concrete |

LS / LSX | All load capacities and jib lengths | Check the suitability of the building floor | With dowel plate |

| VS | Up to 500 kg for all jib lengths; from 500 to 3200 kg depending on the jib length |

|||

| Existing floor of building or concrete ceiling, normal concrete or steel fibre concrete |

LS / LSX | All load capacities and jib lengths | Check the suitability of the building floor | With intermediate plate |

| VS | Up to 1000 kg for all jib lengths; from 1250 to 5000 kg depending on the jib length |

Are you interested in a pillar slewing jib crane with floor mounting? Then request a quote now!

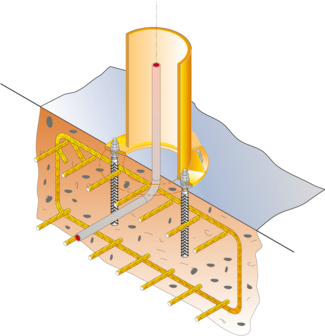

Mounting on the foundation using anchor bolts

Are you planning on using a jib crane for your new building and would like to put the crane into immediate use for your purposes?

Then use the classic anchor rod mounting type for pillar slewing jib cranes which are cast into the concrete foundations when the base plate is created, for example.

The anchors and a steel template are included in the ABUS scope of delivery. The template assists in the precise positioning of the anchor and the alignment of the anchor cage.

You will also receive all necessary specifications for creating the foundation, including the reinforcement material (in accordance with DIN 1045-1) from ABUS.

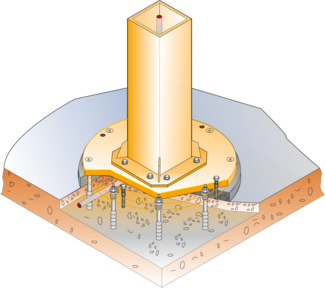

Mounting on the foundation using ABUS ideal anchor screws

Are you planning a new building and would like to use a jib crane at a later point in time?

Then the ABUS ideal anchor screw is the intelligent solution for this - whenever the later crane location must initially remain freely accessible and able to be traversed.

The anchor rods are divided into two parts and are connected together using joint tubes. The closing ground level joint tubes are protected with caps to ensure no contaminants can enter inside.

The jib crane can be installed at a later point in time by screwing threaded bolts into the joint tubes.

The anchors and a steel template are included in the ABUS scope of delivery. The template assists in the precise positioning of the ideal anchor screws and the alignment of the anchor cage.

You will also receive all required specifications for creating the foundation, including the reinforcement material (in accordance with DIN 1045-1) from ABUS.

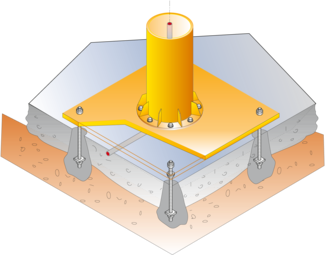

Mounting on a concrete floor/concrete ceiling using dowel plate

Do you have an existing concrete floor or a concrete ceiling (C20/25 to C50/60) and would like to install a jib crane onto this?

Then utilise the flexible option of mounting the crane using special dowels. For jib cranes of type LS, LSX or VS (up to 500 kg), this is a common solution for all load capacities and jib lengths. This mounting system is also frequently used for jib cranes with load capacities from 500 to 3200 kg, depending on the jib lengths.

The fischer dowels specially designed for dynamic loads are used here. To avoid the risk of collisions, the round dowel plate is designed so that no disruptive part protrudes out from the top.

In addition to the injection anchors and the dowel plate, the grouting ring and the grouting mortar are included in the scope of delivery.

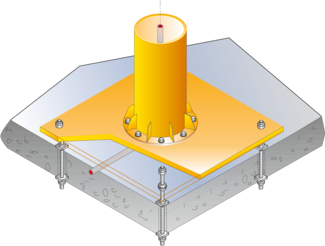

Mounting on the concrete floor using intermediate plate

Do you have a finished concrete floor made from standard concrete (C25/30) or steel fibre concrete and would like to install a crane on top of it?

Then mounting using a square intermediate plate is a very suitable option. Here the base plate is drilled through using a core drill and mortised into the lower area to create good bracing after the deployed anchors are grouted in.

ABUS supplies the intermediate plate. We are also happy to expand the delivery to include the required floor anchor, mortar and formwork material.

Mounting on a concrete intermediate ceiling using an intermediate plate

Is there a concrete intermediate ceiling in your building (C25/30), which a jib crane should be set up on?

The ABUS intermediate plate makes this possible. The intermediate plate is mounted with anchor bolts after drilling through the concrete ceiling.

The ABUS scope of delivery consists of the intermediate plate. We will gladly also supply the appropriate anchor bolts, the mortar and the formwork material.