HB-SYSTEMS

The HB-System is one of the most successful developments in lifting and material handling technology, combining the effectiveness of a stationary hoist with the mobility of an overhead crane, efficiently and cost-effectively.

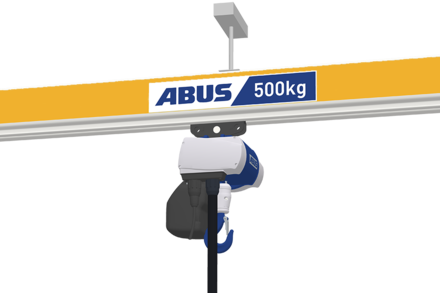

Monorail

The ABUS monorail specialises in lifting loads locally and in linear point-to-point transport. With the help of curved sections your hoist is able to travel through the building exactly as you need it to. Workstations could be linked in this way if required or the crane could be adapted to fit individual machinery locations.

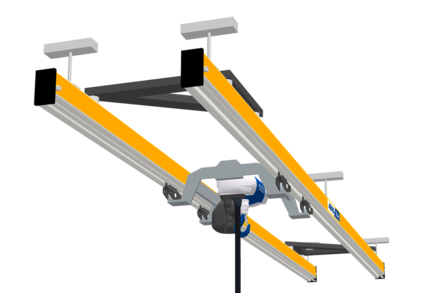

Product details Price enquiryDouble-rail system

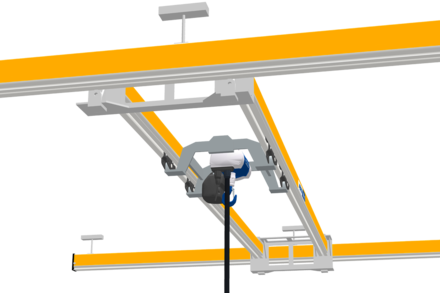

Two crane tracks are suspended in parallel for the ABUS double rail system with the hoist suspended between them. The loads are distributed more evenly meaning less loading for the building structure. Wider suspension spacing is possible.

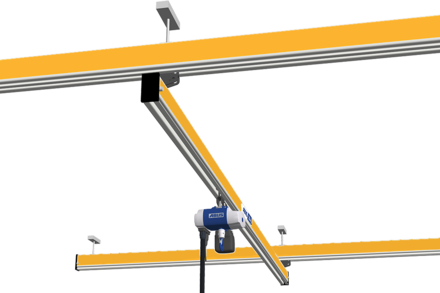

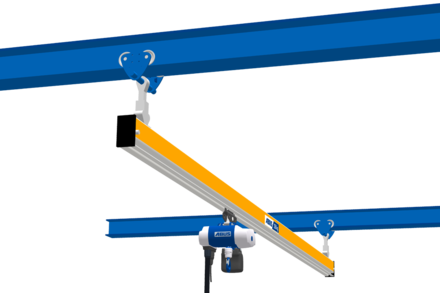

Product details Price enquirySingle girder crane EHB

The ABUS single girder crane EHB is the most straightforward HB system solution for area-coverage materials handling within buildings. The EHB is a very light crane due to the simple construction of two crane tracks and one crane girder which makes it easy to move the EHB manually. This crane is ideal to be installed in lightweight buildings with low load-bearing ability.

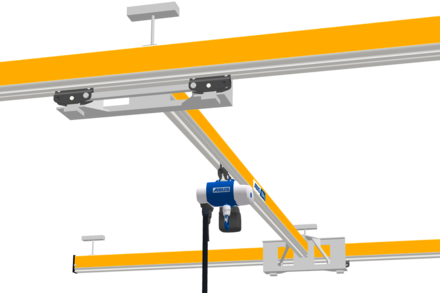

Product details Price enquirySingle girder crane EHB-X

The EHB-X is your answer should the building height of the EHB prove to be insufficient. The crane girder of this single girder crane does not run underneath the crane tracks but between them. The total height of the crane is equal to the height of a single profile. A vastly improved lifting height is achieved. This can be very useful if high machinery in the transport area needs to be negotiated.

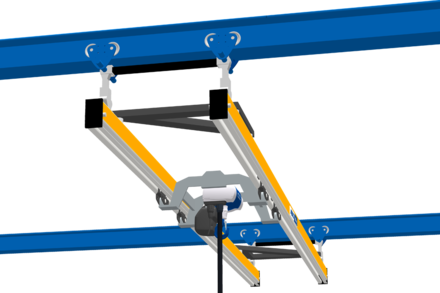

Product details Price enquiryDouble girder crane ZHB

The ABUS double girder crane ZHB is our answer for heavy loads combined with area-coverage transport. The ZHB is also characterised by long crane spans. The ABUS chain hoist is also suspended between the crane girders making for an optimised lifting height.

Product details Price enquiryStooled-up double girder crane ZHB-X

The ZHB-X is your answer should the building height of the ZHB prove to be insufficient. The crane girder of this double girder crane does not run underneath the crane tracks but between them. The total height of the crane is equal to the height of a single profile. A vastly improved lifting height is achieved. This can be very useful if high machinery in the transport area needs to be negotiated.

Product details Price enquirySingle girder crane EHB-I

The ABUS single girder crane EHB-I is a good solution for area-coverage material transport in buildings that have existing rolled-section girders fitted at a distance appropriate for crane tracks. The lightweight crane girder consists of a hollow profile suitable to run directly on this rolled-section girder crane track when combined with the two underslung trolleys.

Product details Price enquiryDouble girder crane ZHB-I

The ABUS double girder crane ZHB-I is our answer for heavy loads combined with area-coverage material transport. The ZHB-I is also characterised by long crane girder lengths. The crane travels directly on crane tracks consisting of rolled-section girders. The ABUS chain hoist is also suspended between the crane girders making for an optimised lifting height.

Product details Price enquiryMountings

You can select a suitable solution for your building construction from a variety of mounting options.

Product detailsFAQ

Light crane systems like the HB system are versatile and designed for transporting light to medium loads. They can move loads of up to 2 tonnes safely and precisely and are ideal for operating ranges where flexibility and efficiency are required.

HB systems are particularly suitable for compact, manageable loads, such as:

- machine parts

- workpieces and assemblies

- tools or fixtures

- packaging material or products in warehouse logistics

A major advantage of the HB system is its flexible installation: it can not only be mounted on the ceiling to save space, but also on free-standing gantries that surround the operating range. This makes the system ideal for applications where ceiling mounting is not possible, for example, where the ceiling load is limited or in buildings without suitable mounting options. An ABUS advisor is happy to help plan an HB system, even in complicated circumstances.

The ABUS light crane system (HB) is an excellent solution for various scenarios, especially when flexibility, modularity and efficient use of space are required. It is particularly suitable for applications with limited ceiling height. The compact design and the option of mounting the crane on an existing ‘I’ beam make optimal use of the available space, without the crane requiring much space above, and loads can be transported overhead even over long distances.

Another outstanding feature of the HB system is its high modularity. It can be flexibly adapted and easily expanded or converted as needed. If the need for higher load capacity or additional range arises over time, the system can be easily adapted. The HB system is particularly suitable for handling light to medium-heavy loads and is often used in production facilities, workshops or warehouses where such loads have to be moved regularly. This flexibility without high investment costs in complex crane installations offers an economical solution in goods logistics. The modular system and the wide range of mounting options can quickly make it difficult to get an overview. It is therefore always worthwhile to get advice from an ABUS advisor.

Integrating an HB system into an existing building is usually not a problem. A major advantage of the ABUS system is its flexibility and adaptability, which makes it easy to install in both new and existing buildings. However, there are some aspects that need to be considered to ensure optimal functionality and security.

If the building has a suitable ceiling construction, the HB system can be mounted directly on the ceiling. However, if the ceiling does not have sufficient load capacity or suitable mounting points, the system can be installed on free-standing gantries. These gantries can be individually adapted to on-site conditions and enable flexible installation regardless of the existing building structure.

Another important point is the space available in the building. The system requires sufficient space for the rails and the crane's area-wide range of motion. Obstacles such as columns, wiring or ventilation ducting must be checked in advance and, if necessary, bypassed to ensure smooth operation. It is also important to check the load capacity of the building construction if ceiling mounting is planned. A structural engineer can clarify whether the existing roof supports can take the additional weight of the system and the loads. If this is not possible, free-standing gantries offer a safe and flexible alternative.

Thanks to its modular design, the HB system can be individually adapted to on-site conditions. Rail guides, spans and load capacities can be configured to optimally meet requirements and spatial conditions. Although installation in an existing building can be somewhat more time-consuming – especially if adjustments to the supporting structure are required – installation is still straightforward and efficient.

As a rule, an existing building is not an obstacle to the integration of an HB system. With the right planning and any necessary adjustments, the system can be installed without any problems and offers a flexible and efficient solution for your requirements. Technical advice and an on-site inspection are recommended in order to analyse the on-site conditions precisely and to find the optimal solution for your building.

Operating a manual light crane system is usually easy and does not require excessive physical effort, as the system is designed to allow the operator to move the load with minimal force. The manual HB system uses a push trolley that allows the operator to move the load efficiently by pushing the crane by hand.

Thanks to optimal mechanical properties and simple operation, the operator does not have to exert great force. This ensures ergonomic operation and minimises physical strain, which is particularly advantageous when the crane is used frequently. However, if the crane is used for longer periods or for heavier loads, the use of an electric trolley as a supporting drive mechanism can make the job easier.

Optimal solutions for all areas of application

The principle of modularity – this is what ABUS stands for – offers individual, customized and at the same time efficient solutions.

We can offer a diverse range of solutions suitable for every situation – regardless of the condition of the ceiling structure. Our standardised ceiling connection options can be adapted to almost any shape and material – ranging from steel beams or reinforced concrete ceilings to concrete beams or wooden trusses. When planning our systems, we keep the number of components used as low as possible. This simplifies the installation of the crane system, helps to avoid errors and saves time.

Freestanding steel structure solutions are normally used where the ceiling structure is either not suitable or available to support the crane system. Cantilever or T-supports developed and standardised by ABUS make implementation considerably easier – from planning to installation.

Suspended rail systems from ABUS are the optimal transport solution in many areas of application. They are particularly popular in logistics, as workplace cranes, in toolmaking and engineering (e.g. as machine lifters), metal construction as well as in the plastics industry and also with suppliers to the automotive industry.

Thanks to our smooth-running end carriage, little force is required when manually moving the cranes and trolleys on the suspended rail. It does not make any difference whether you use steel or aluminium profiles. This means a plus in ergonomics and effortless working for your employees, who use our suspended rail system every day.

ABUS suspended crane: efficiency and flexibility in the work place

A suspended rail system offers the efficient transport of workpieces and will considerably optimize your working processes. For profiles made of aluminium, we are further expanding this product range. Thanks to the low service weight, fast positioning options and smooth crane movements are possible. The aluminium profiles, which are manufactured using an extrusion moulding process provide high quality running surfaces which ensures smooth running, which is especially beneficial for main girders that are moved by hand.

The material and production flow in your company can change at any time – thanks to our modular construction, you can always convert or expand your ABUS HB system. Existing crane systems can be modified, different profiles made of steel and aluminium can be combined and the distance between the suspension points for mounting your profile track can be optimised. The load capacities can also be increased if the construction is statically suitable.

Suspended rail systems from ABUS

With its suspended rail systems, ABUS offers a wide range of services in flexibility, quality, technology and economy – All traits ABUS are recognised for in the market. Our recipe for success: a customised solution for your application based on standardised components.

You can also achieve the maximum possible efficiency with our electric chain hoist, which is used in combination with our light crane systems. For double girder cranes, it is installed in the trolley frame, which sits between the crane girders, so that an optimum hook height can be achieved even with low connection heights.

Together with you, we will work together to find the optimum crane system in a personal consultation on site – whether it be a single-rail trolley track or double-rail trolley track, single girder crane or double girder crane. With these crane systems, we are always “very close to the employee”.

For working with loads above 2 t and for load capacities of up to 120 t, we recommend our overhead cranes (single girder, double girder or underslung cranes) which can accommodate spans of up to 40 m (depending on the load capacity) and offer an ideal use of space as well as superior lifting equipment capabilities. As workplace cranes, our slewing jib cranes support your employees in coping with daily loads. These can be designed with a load capacity of up to 6.3 t as a pillar jib crane and of up to 5 t as a wall-mounted jib crane.

Put your trust in ABUS Crane Systems when you need a quick and bespoke offer.