Subsea Innovations at high level with ABUS EOT cranes

Formed in 1985 by a team of experienced engineers and diving professionals, Subsea Innovation (www.subsea.co.uk) is a company dedicated to delivering state of the art engineering products to the offshore Oil & Gas and Energy industries throughout the world.

Through its dedicated team of highly skilled Engineers, Designers and Technicians based in the North East of England, Subsea Innovation continues to retain its status as a recognised world leader in the design and manufacture of highly sophisticated marine engineering solutions. Their key customers include Subsea 7, Deep Ocean, Saipem, Technip, BP, RasGas and Total Marine Technology.

The extensive product range includes: Offshore Equipment Handling Systems, Pipeline Repair & Recovery Systems and Subsea Sealing Systems.

With an order book bulging at the seams, Subsea Innovation had outgrown its 20,000 square foot facility at Darlington and took the brave decision to purchase land and to design and build a purpose built office and manufacturing facility. The unit was completed in September 2014 and is 40,000 square feet in size on a 5 acre site giving room for further growth in the future. The company sells its products all over the world with a turnover of £10m, employing over 50 staff.

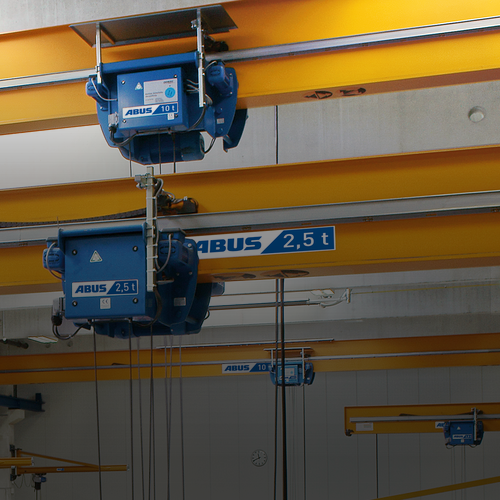

Part of the investment were four ABUS overhead cranes. A pair of these are 5 tonne Safe Working Load single girder ELK type cranes with a span of 17.4 metres and GM1000 hoists with a 6 metre hook path, and these work on the smaller rigs produced by Subsea.

A further larger pair comprise two ABUS 25 tonne Safe Working Load ZLK double girder overhead cranes with a span of 23.5 metres and a GM5000 crab unit with a 15 metre hook path, and were the ideal solution to enable Subsea engineers to assemble their larger fabrications.

All four cranes featured travel motion limit switches to ensure that the crane is automatically slowed and stopped as it approaches the extent of its travel run in any direction. They also feature the ABUliner inverter control technology to enable operatives precise stepless control of the loads lifted.

The larger cranes had the added feature of microspeeds on the hoisting and lowering motions to offer the crane user an even finer accuracy and precision in positioning the fabricated subsea equipment onto its locating bolts during the build programme.

These ZLK cranes are fitted with stooled down DQA crab unit trolley to reduce the total crane envelope and offer the maximum achievable height of lift required due to the height and bulk of the Launch and Recovery Systems and other equipment manufactured.

All cranes were supplied with radio remote control device to enable users to operate the cranes whilst not having to stand directly beneath them, which has obvious advantages in the case of large fabricated loads. The crane delivery and installation was undertaken by ABUS’ UK based subsidiary – ABUS Crane Systems Ltd.(www.abuscranes.co.uk) whose customer base strongly reflects the UK’s notable link with the sea, having recently supplied cranes to maritime universities, lifeboat stations, marinas and historic dockyards.