ABUS cranes systems at South Devon Railway

The South Devon Railway (www.southdevonrailway.co.uk) is the oldest steam heritage railway in the South West of England, having first re-opened in 1969, who aim to literally transport visitors back in time to the bygone steam-train era whilst also offering every modern facility for their enjoyment.

The award-winning scenic seven-mile railway line is run as a charitable trust and one of the top ten heritage railways in the UK, whose warm welcome and nostalgic ambience is clearly evidenced by many positive comments on travel sites such as Trip Advisor.

In June 2014, it carried its two millionth passenger since 1991, and has 13 steam engines, 12 diesels and a 30-strong fleet of historic coaches, all of which need repair and maintenance, which is undertaken in-house.

This strong reputation for engineering work ensures that South Devon Railways are an unusual, if not unique, commercial tourist venture in their area, and allows them to also supply the rest of the UK railway industry and heritage railways with brand new components.

With an annual turnover close to £3 million and having some fifty paid staff, it is still run predominantly by some 600 regular working volunteers filling roles such as Driver, Fireman, Guard, Signalman, Station Master and Duty Officer, all requiring specialist, safety-critical training and very high levels of competence, as the volunteer railway is still governed by the same rules and requirements as the commercial national rail network.

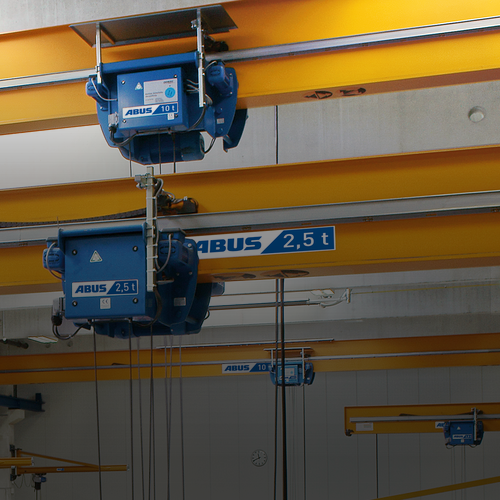

Recent investment in the engineering workshops include two ABUS overhead cranes, both of single girder design. Both of these boast an 8 tonne Safe Working Load and GM3000 wire rope hoists. The smaller of these cranes with a span of a little under 4 metres works in a side bay on component repair and refurbishment tasks, and is well served by a hoist with a 6 metre hook path.

The larger crane spans the 9.15 metres of the main bay, and is used on tasks where components are removed from or fitted directly onto the trains themselves. Consequently this main bay crane is stooled up to take full advantage of the available headroom, and ensure that components can be lifted over the locomotive engines. The stooling from the top of the crane rail to the top of the crane is 1100 mm. The subsequent height of this main bay crane necessitates that the wire rope hoist fitted to this crane has a 10 metre hook path.

Both cranes featured travel motion limit switches to ensure that the crane is automatically slowed and stopped as it approaches the extent of its travel run in any direction. They also feature the dual speed lifting and travel motions which are fitted as standard to ABUS cranes, enabling the crane user to have the option of the slower speed for tasks requiring precise positioning.

The crane delivery and installation was undertaken by ABUS’ UK based subsidiary – ABUS Crane Systems Ltd. (www.abuscranes.co.uk) whose customer base reflects the UK’s ongoing rail infrastructure investment, having recently supplied cranes to the Eurostar and London Crossrail projects, as well as routine train maintenance shed lifting equipment for various Main Contractors.

Photos by Paul Pridham (SDRE)